Written by Sarah Haberecht President of the Worlds Poultry Science Association – Victorian branch. Read full bio.

As the global population grows, pressure is growing within the animal production food chain for transparency, particularly in animal welfare, environmental sustainability, and public health. As we move forward, the poultry and swine industries must provide more documentation to show compliance in response to stricter governance within these areas. The increase in reporting may initially seem like more work for processors, farmers, and suppliers along the food chain, but with Precision Livestock Farming (PLF) programs, technologies, and equipment, this compliance can become a tool creating efficiencies instead of increased work. Here we turn to 3 primary techniques, sensors, big data/machine learning/AI, and blockchain.

Technology and its impact on animal welfare

Animal welfare monitoring focuses on identifying and pre-empting negative health impacts from disease or environment/equipment, using real-time data. Sensors inside the poultry house can include monitoring the environments, such as temperature, humidity, and CO2 sensors, and others like biometric sensors, which monitor the animal movements, noises, temperature, and bodyweights. Installation of these sensors is only part of the solution here; the next step is to use this data to improve processes. Big data, data mining, machine learning, and artificial intelligence can take these complex data points and improve welfare by analyzing real-time environmental conditions and alerting the grower immediately when a threshold breach occurs. Monitoring animal weights in the house can indicate health issues early by highlighting slower growth than AI predictions, allowing earlier investigations and reducing potential impacts; for example, reduced feed intake may signify gut health issues such as coccidiosis.

Increasing sustainability with technology

Reducing the on-farm production of carbon emissions can also be achieved via the PLF use of sensors to reduce waste. With PLF, we can monitor, through sensors and new technologies such as thermal imaging cameras, and then adjust energy inputs used for heating and cooling of animals by paying closer attention to animals physically rather than relying on standard curves and external temperatures. When used to gauge overall animal comfort, the accurate and constant measuring from sensors can alert to potential health issues when changes such as body temperature are recorded outside the comfort threshold and used as an indicator of disease infection or heat stress, allowing for faster diagnosis of health issues, and improving welfare.

Waste reduction is a measurement of reducing our carbon footprint to improve environmental sustainability. Sensors are advantageous here also as monitoring feeder lines, feed intake, and water consumption will result in earlier warnings of possible equipment issues. A spike in water consumption may be a burst waterline; speedy recognition will prevent water damage to litter and potential ammonia level increases. Similarly, control pan failure on a feeder line can set off alarms when running times are longer than expected, and the alarm can be raised, reducing the spillage and wasted amount. Utilizing sensors in PLF will help provide a more stable and optimal environment for birds while helping to reduce carbon emissions on-farm.

The higher level of interest in social awareness of the food chain is no longer mainly driven by welfare compliance but environmental sustainability and issues relating to public health. Data collected during production is now required for auditing and compliance and as a source of consumer information impacting labeling and product sales. The level of detailed information required by regulatory bodies, auditors, the processing plant, and consumers is overwhelming for the producer.

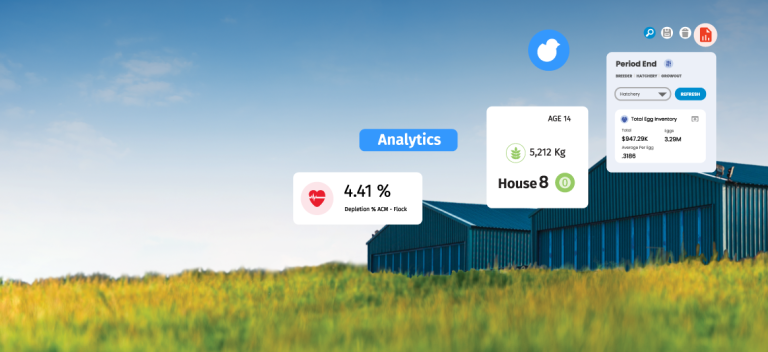

Driving production efficiencies and productivity with Precision Livestock Farming

The administrative load for agriculture has increased dramatically in the last five years, but this doesn’t need to be a burden with PLF. As mentioned above, the use of sensors to automate the vast array of data and then a software database such as MTech Systems offers, the data is then cleaned, sorted, stored, analyzed, and sent to every end user in the format required. This process can be completely automated or sent for approval before release. The data can be used for instant alerts on the farm, in daily, weekly, and on-demand reports, in business analytics for management, costing comparisons, audit reports for internal and external bodies, linked to blockchain processes, or any other format that may be required. Using a single source for data collection for precision livestock farming such as the MTech Systems software and hardware sensor options provides more substantial compliance and a more robust traceability tool by reducing any variability in subjective measures, data entry errors, and delays in information availability.

Sensors, big data/machine learning/AI and blockchain, improve traceability and animal welfare and when used together as tools of precision livestock farming, providing production efficiencies and reliable, accurate end-user information.

It’s exciting to think about all the ways precision livestock farming can help improve production efficiencies. Learn how you can harness the power of innovation in your production to improve flock performance and profitability in this free PDF.

Sarah Haberecht

After beginning her career in the poultry livestock industry, Sarah moved into the stockfeed industry as a technical specialist. Her experiences on rearing, breeder and broiler farms, hatchery quality assurance, livestock planning and technical farming services provide a sound base to draw on. In recent years Sarah has undertaken the responsibilities as the Poultry Information Exchange Conference Vice President and, more recently, as the President of the Worlds Poultry Science Association – Victorian branch. During the industry roles, Sarah completed her Masters in nutrition and is currently completing a PhD where she is investigating macroalgae in poultry feeds. Her interests lie in poultry gut health and practical science ideas for poultry production, which is continued further now with the role at MTech Systems, where she hopes to help the poultry and swine industries get the most from precision livestock farming resources.