From time to time, companies must reinvent themselves and their processes to ensure their sustainability in an ever-changing market. The meat industry has gone through several paradigm shifts in recent decades. For example, when we talk about farming, new technology has allowed speeding the animal raising cycle and reducing costs. Thanks to automation and artificial intelligence (AI), producers are capable of mapping thousands of farms and animals in real-time.

Research and Development (R&D) has also opened the doors to significant advances in the use of nutritional components that increase the productivity of meat companies and to the automation of production processes.

In Logistics and distribution, we can cite the revolution of ‘last-mile delivery,’ which occurred due to applications launched such as Uber Eats, Rappi, and iFood, which connect end-consumer to restaurants.

The case for the supply chain in the meat industry is not different.

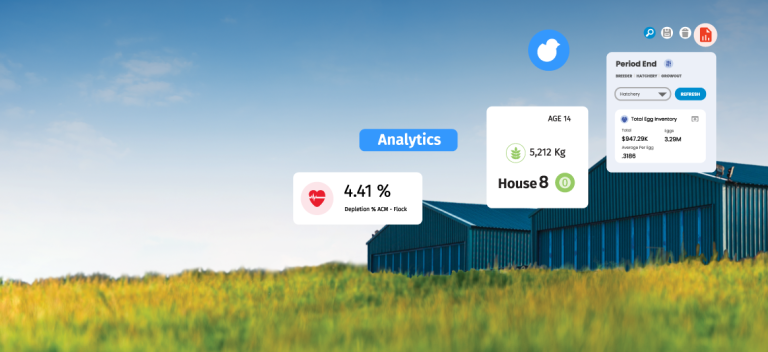

Companies’ planning cycles have become more complex as consumers require products faster, with higher quality, and lower costs. Therefore, meat companies need software to optimize their supply chain plans and scenarios and support them in making quick and informed decisions in all supply chain stages, from slaughter to packaging and delivery. Technologies based on linear optimization, machine learning, and artificial intelligence exist. However, studies from Gartner show that most companies rely on Excel spreadsheets to plan their supply chain. By doing so, those companies are missing important information and collaboration and assuming the risk of human errors.

That happens because deciding on the best Supply Chain Management software might be challenging. There are several variables and conditions to be considered. Having worked for several years in one of the largest meat companies globally and tested several software solutions, I identified some key success factors that must be considered in this process. Here are the five main factors a leader must consider while deciding on the proper Supply Chain Management (SCM) Software:

1. Support for all Planning Levels

In SCM, there are three levels of planning: strategic planning, which considers the long term, usually over a year, and addresses decisions in investments, expansions, and others; sales and operations planning (S&OP), related to the mid-term term, one to twelve months, and addresses market demand fulfillment and supply chain optimization; and sales and operations execution (S&OE), which considers short-term – shifts, days and weeks — and handles the supply chain deviation and sales orders fulfillment. Those three levels of planning connect the short-term action to the company’s vision of the future and manage supply chain trade-offs involving service level, operations efficiency, inventory, and profitability. Consequently, evaluating if the SCM software supports and connects the three planning levels is paramount.

2. Assistance with Decision Making

The second aspect of SCM software is the assistance with decision-making in the short and long terms. The meat industry supply chain system is complex and manages several stages and variables. For example, the agriculture receives inputs such as eggs, grains, water, and energy and uses their farms to raise animals; the factories receive, slaughter, and transform the animals into finished goods; the logistics deliver those goods to supermarkets, restaurants, and others; and commercial and marketing are responsible for selling the products. These stages of a supply chain system also need resources – such as humans, money, equipment, etc. Humans and Excel spreadsheets alone cannot deal appropriately with that number of variables and conditions. Using powerful algorithms and technologies such as solvers, artificial intelligence, and machine learning are essential to support managerial decisions about the supply chain organization.

3. Agility and User Friendly

Supply chain planners enjoy working with Excel spreadsheets because they can quickly and intuitively create customized graphs and pivot tables. They sacrifice the quality of the analysis and calculation for usability. Moreover, those planners manage several inputs and deviations in their supply chain daily. For them, time is a precious asset! Therefore, an SCM Software must be easy to operate, including maintaining records, efficient interfaces, production line visibility, customizable reports, and others. It also must be agile, delivering planning scenarios in just minutes.

4. Collaboration & Compatibility

As previously mentioned, a meat industry supply chain involves several areas and stages – agriculture, production, sales, marketing, logistics, etc. The right SCM Software allows collaboration among the diverse areas in a company. For example, the production team is responsible for capacity, efficiency, materials, and producing the right mix of goods; the sales team is responsible for forecasting the demand or issuing sales orders; the logistics team is responsible for contracting freights and warehouses and delivering products to the customers; the controllership team is accountable to information such as cost and taxes; the list of areas that contribute or receive information from the supply chain planning can continue. The best SCM Software is compatible with the company’s existing software and supports the collaboration and the flow of information among distinct areas.

5. Process Improvement

Finally, supply chain planning is an ample process, with multiple tasks and levels that involve several interactions among the organization’s departments. A software objective is to help companies to manage their processes more effectively. Not having established processes and information flow negatively impacts the software performance. That is why technology companies that are segment leaders support their clients in re-thinking and improving their supply chain planning processes. That is critical for long-term, reliable partnerships and to increase profitability.

I hope you find this this article useful and helped you as a guide on your decision about SCM Software for the meat industry. Following those five tips is vital for your supply chain planning success.

Stay tuned for future articles and guides on more aspects that any production company must check when buying software such as reliability, stability, security, assistance, and more.