MTech Systems is Changing the Landscape while Opening New Opportunities for Success.

Feed mills are undergoing rapid transformation driven by technological advancements, changing consumer preferences, and sustainability concerns. As the world’s leading provider of software solutions for the feed industry, MTech Systems is committed to driving innovation and sustainability across the feed production landscape.

From digitalization and automation to sustainable practices and ingredient optimization, the feed mills of the future are poised to revolutionize animal nutrition and enhance agricultural sustainability.

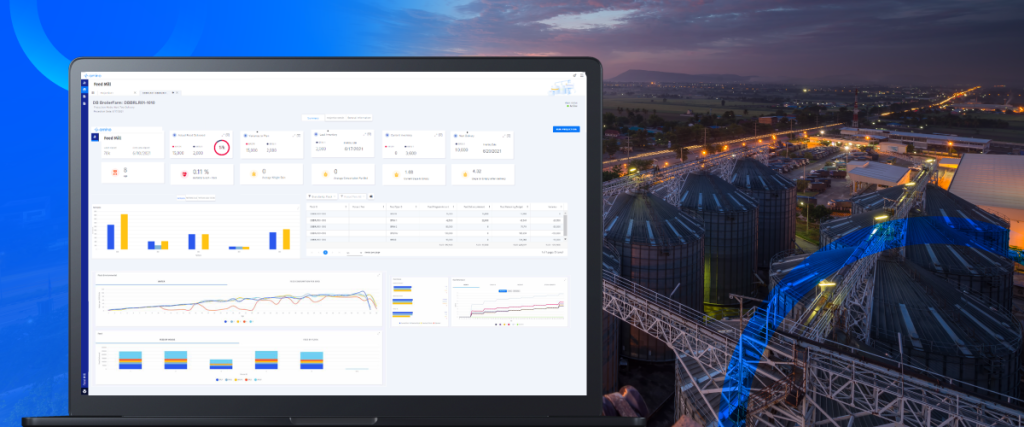

Amino, our crown jewel software comes equipped with cutting-edge management and planning capabilities to help producers unlock new opportunities for efficiency, quality, and environmental stewardship.

Now is the time to leverage digital tools, data analytics, and sustainable practices to meet the increasing demand while minimizing costly waste, clerical errors, and environmental impact.

The Evolution of Feed Mills

Feed mills have evolved significantly over the years, from manual operations to highly automated facilities equipped with state-of-the-art controllers and sensors.

Advances in equipment design, process optimization, and ingredient sourcing have enabled feed producers to improve efficiency, consistency, and product quality.

Today, feed mills are transitioning towards digitalization, automation, and sustainability to meet the growing demands for animal nutrition while minimizing resource consumption and environmental footprint.

The Challenge… s.

The feed industry faces several challenges, such as:

- Ingredient Sourcing: Ensuring a consistent supply of high-quality ingredients is essential for producing nutritious and cost-effective feed.

- Quality Control: Maintaining product quality and safety standards throughout the production process is a constant challenge for feed mills.

- Environmental Impact: Feed production has significant environmental implications, including resource consumption, greenhouse gas emissions, and waste generation.

- Regulatory Compliance: Compliance with stringent regulatory requirements adds complexity and costs to feed production operations.

- Market Dynamics: Fluctuations in commodity prices, consumer preferences, and trade policies pose challenges for feed producers.

Meet Amino: The #1 Feed Mill Management App.

Amino is a comprehensive farm management app designed to streamline operations and enhance efficiency across the board.

As a cloud-based app, tailored specifically to the feed industry, Amino offers features such as production planning, inventory management, quality control, and real-time analytics.

Access the tools and insights you need to optimize your operations throughout the supply chain and enjoy the ease of managing with a proactive approach.

Amino’s Feed Mill-Specific Innovations.

The future of feed mills lies in embracing innovative technologies to enhance efficiency, sustainability, and product quality. Our key innovations include:

- Digitalization: Leveraging digital tools and data analytics to optimize feed formulation, production scheduling, and quality control.

- Automated Projections: Implementing automated systems for ingredient handling, mixing, and deliveries to improve process efficiency and consistency.

- Ingredient Optimization: Exploring the impact of alternative ingredients and feed additives to improve nutritional value, reduce costs, and minimize environmental impact.

- Full-Case Traceability: Implementing blockchain technology and other traceability solutions to track ingredient sourcing, production processes, and product distribution.

- Sustainability: Adopting sustainable practices such as energy efficiency, waste reduction, and circular economy principles to minimize environmental footprint.

Future-Proof Features

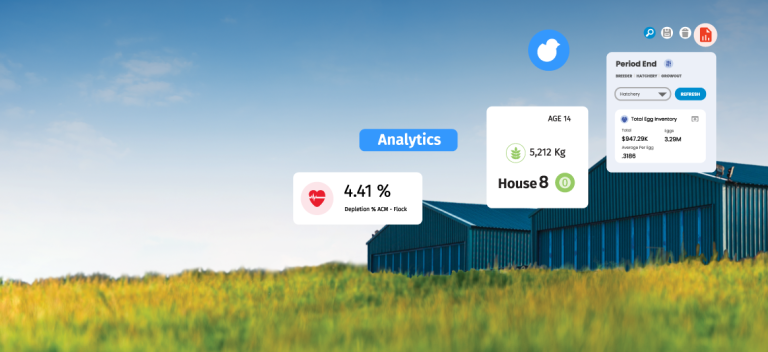

Amino offers a range of scalable features specifically tailored to the feed mill industry, including:

- Production Planning: Plan production schedules based on market demand, inventory levels, and processing capacity.

- Inventory Management: Track inventory levels of live birds, feed, and other inputs to ensure adequate supply and timely delivery.

- Quality Control: Monitor key quality indicators, such as bird health, weight gain, and mortality rates, to ensure product quality and safety.

- Real-time Analytics: Access real-time analytics and dashboards to monitor performance metrics, identify trends, and make data-driven decisions.

- Integration Capabilities: Integrate Amino with existing systems and third-party applications to streamline workflows and enhance data interoperability throughout the supply chain.

In conclusion, the future of feed mills is characterized by innovation, sustainability, and efficiency.

By embracing digitalization, automation, and sustainable practices, feed producers can meet the evolving needs of the livestock industry while minimizing environmental impact.

As a trusted partner in feed production, MTech Systems is committed to supporting feed mills in their journey towards a more sustainable and resilient future.

Recommendations for Future Feed Mills

To thrive in the evolving feed industry landscape, we recommend the following:

- Embrace digitalization and automation to optimize feed formulation, production processes, and quality control.

- Invest in sustainable practices to minimize environmental footprint and enhance corporate social responsibility while also reducing costly waste.

- Collaborate with industry partners, suppliers, and customers to drive innovation and address shared challenges.

- Stay informed about emerging technologies, market trends, and regulatory developments to maintain a competitive edge.

- Continuously monitor and evaluate performance metrics to identify opportunities for improvement and innovation.

By implementing these recommendations, feed mills can position themselves for success in the dynamic and increasingly sustainable feed industry.