In a recent Wattagnet interview with Christine McCracken executive director for animal protein at Rabobank, Christine highlights that feed prices are projected to rise again in the coming year.

Poultry feed and raw material costs are unpredictable. This makes cost allocation and planning challenging for producers. With the volatility of the market, poultry businesses need reliable data to help them understand what factors are impacting their feed costs, so they can plan accordingly.

In this article, we will unpack why FCR is not the only factor you should think about when looking to reduce feed costs. In addition, we will introduce you to a few ways that smart farming technologies like artificial intelligence can assist you when you’re looking to cut costs and improve performance.

Improving FCR is only one way to lower feed costs

When setting out to lower feed costs producers generally start by looking at how to improve FCR but there are many other factors that can affect feed costs. And improving FCR won’t always save you the most money in the long run. For example, if you are trying to reduce feed costs and you get to an FCR of 1.6 you might feel good about this but what if the feed you are feeding is really expensive, then are you truly cutting costs? For example, you may see some blocks of super great FCR but their feed cost is really high and at the end of the day when you transfer that to the cost of the flock you know that flock may have gotten you $50,000 but you spent $25,000 on feed is that necessarily better than a flock that only gets you $45,000 but you spend $15,000? In this case, you are still $5000 ahead. Or what about the delivery costs for the feed? If you have a good FCR but don’t consider all the overall cost factors that impact feed costs are you really accomplishing your goal?

This is why it is so important to have a centralized database that allows for easy analysis when setting out to improve any KPI on your farm like FCR.

How to get a fuller picture of feed cost

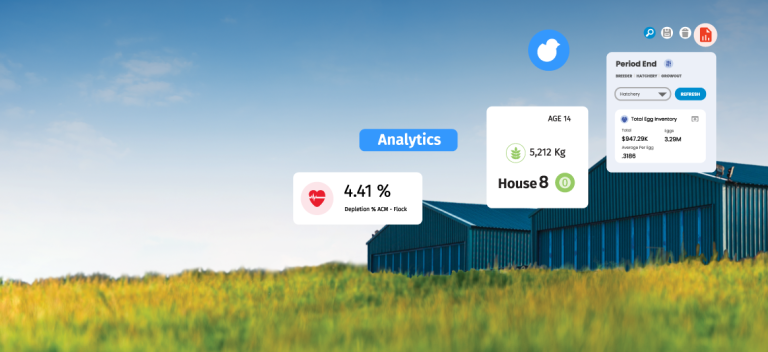

Having a good management system in place that combines costing and performance data can help you uncover all the factors that need to be adjusted so you can save the most money in every area of your business, including reducing feed costs.

Below are the steps we recommend taking if you’re looking to get more out of your data.

Centralize your data: Integrating all data sources into one provides visibility into the whole story. Having your costing and performance data separated will not allow you to see how each factor impacts the other.

Optimization and testing: Once you have the big data picture you will be able to easily see what factors you may need to tweak, as well as you’ll also be able to measure the effectiveness of those changes.

Improve planning and reporting: The more accurate your data is, the more reliable your reports will be. Having reliable reports allows for deeper insight so you can make more informed decisions.

Going from descriptive to prescriptive actions

Tracking key information and analyzing it efficiently is the first step to optimizing production, but it keeps producers in a reactive state. Understanding what happened and why is important but it’s only a starting point to improving performance and production.

Today’s technologies like artificial intelligence allow us to go from looking in the rear-view mirror to now seeing what will happen in the future. Not only this, but the AI machine learning models also give us the prescriptive insight to see how we can make it happen.

Tightening the supply chain using artificial intelligence

One of the biggest ways to save on food costs is to be able to accurately predict bird weight. When you’re able to forecast what weight, the bird needs to be to send them to the plant, you’ll be able to project the exact amount of food needed, which minimizes food reclaim, allowing for less trimming at the plant. MTech Systems IoT technologies are the best weight prediction tools the market has to offer.

Accurate feed projection and weight prediction are just a few of the many exciting things you’ll be able to do using artificial intelligence, download this guide to see how you can use the power of artificial intelligence to improve your production and planning initiatives.