Taking into account a growing population and shifting diets, the world will need to produce 69% more food calories by 2050, which will in part come from poultry production. This means production will need to increase and so will the amount of data we collect and analyze. Even as it stands, currently over 50% of organizations lack sufficient AI (Artificial Intelligence) and data literacy skills to achieve business value.

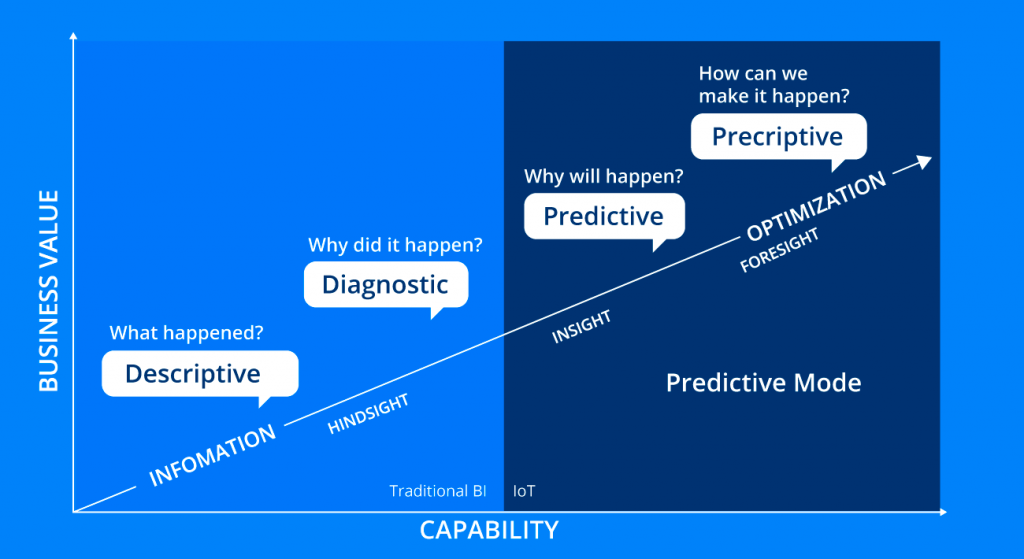

With the right analytics strategy in place, producers will not only be able to responsibly increase production, but they also will be able to optimize for expected results.

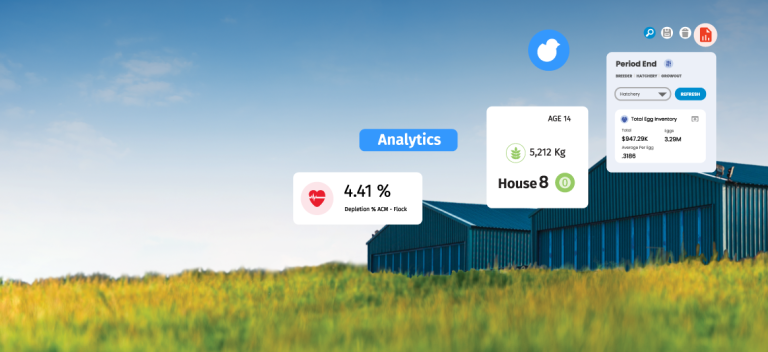

The first step in any analytics journey is to clean up and centralize your data. The next step is to connect your farm to an IoT system to ensure continued data accuracy. All that data will then flow into your data management system to allow you to gather insights faster. The reports inside our system tie performance data to financial data that make it easy to understand key trends and correlations. And tie in the fact that the more data that’s in the system machine learning will activate and automate key insights.

Many other systems operate independently of one another and don’t combine performance and costing data which makes traceability and optimization tough. Our system marries performance data with costing through the entire supply chain.

What happens when you tie live poultry production and financial data together?

Magic. We spoke with our Director of Analytics, and he gave us a few scenarios to show us what is possible when costing is intertwined with production. You can see his examples below.

- Feed cost control: It’s no secret that feed represents 70-80% of overall production costs. With MTech Systems, you can be in better control of fluctuating costs. Our feed mill system controls all ingredients, tracks feed inventory, and provides accurate real-time costing. In addition, our IoT system tracks feed consumption and alerts you of any potential issues. The software can also project how much feed is needed and when it will be needed before you run out of feed. Not only this, but the system will also auto-order feed, so you don’t even have to pick up the phone. All of this works together to lessen feed reclaim, ensure healthy feed consumption and because if we accurately predict feed, then we will have a more accurate cost.

- Accurate grower settlements: Our calculations are very accurate because we have years’ worth of live operational and performance data in our system. All customers need to do is provide us with the grower contracts and the rules can be customized as needed. If grower A meets these metrics, they will be paid x amount per pound or kilo once they reach that plan. We then generate all the journals that are sent to the ERP to make the final payment. Some companies try to handle grower payments in Excel or customize their ERP like SAP, Dynamics, or Oracle to handle them. But building complicated macros in Excel is not only not efficient but the data can be easily manipulated. Trying to build a similar setup in an ERP will be a heavy investment and ERPs are not set up to efficiently run the task of calculating grower payments. We had one customer who spent millions trying to customize their ERP to handle this task and they were unsuccessful and came to us and said they wanted us to handle it in our system because it calculates the settlement perfect for them.

- Visibility into the value of the bird based on actual costs: Because our system can provide all the costs that it takes to produce the animal from feed costs to grower payments to medication and vaccination costs, supply costs to even overhead like labor, it allows producers to see the true cost of production. One example of this is the metric Bird Days which looks at the real-time inventory of the birds on every day of the period. Our system is very accurate on these numbers which means we’re extremely precise on reporting mortality. All these metrics are tied to costs and impact profitability. Not only can we tell how many healthy birds will arrive at the plant, but we also can accurately project bird weight using AI before the birds reach the plant.

Data opens the flood gates

The foundation for all growth is clean data. The use of IoT allows for accurate data to be loaded into the system every 15 mins. With this data, we now know the weights of the animals and how much the birds are consuming. When you have a large reliable data set, you can run it through a Business Intelligence tool to quickly find trends and correlations that will help you to optimize your entire operation for future growth. When you find issues, Data Science can be applied to determine the root cause. Our Data Science team can even predict early farm condemnations at placement. Download this guide to see how you can use Data Science to increase profitability in your production business.