Adapting to the changing needs in the poultry industry requires producers to be agile. Utilizing the right technology will help companies to adjust and remain competitive in a volatile market. In this post, we will outline how supply chain planning software can help planners and poultry organizations to be more efficient and profitable amidst any challenge that may arise.

Using modern long-term planning to turn poultry supply chain challenges into opportunities

Live bird weight accuracy at processing: It’s important to make sure your birds arrive at the plant at the right size and grades in order to meet your demands. Also, to keep your stock levels at the right amount to ensure less waste and more profit. Using processing planning software, you can use long term projects to forecast what are the right size for the birds from the farms for each period. For example, what is your sales forecast for the year? The software uses the projected sales orders using Machine Learning it projects what the optimum bird weights should be for the farms. Feeding this information through your data management system you will be able to see if the weights are matching up to better fulfill your demands. If anything needs to be adjusted, you easily change your plan. These projections are based off historical and real data not standards which means the accuracy is much higher.

Product mix accuracy: With the export market demand slumping hugely and the value of breast fillet dropping from $3.50 per pound to $2 over recent months there is a need to manage product mix much more proactively to maximize the revenue and minimize production costs associated with producing the wrong products.

Sales order execution: Achieving all your orders on time and in full depends on many factors, so having an agile long-term planning approach is important. Use planning software to calculate projections on your actual birds vs. your demands. If there are any issues, the system will show you in advance, so you will have the time to adjust as needed. Bottlenecks or factors that might cause delay such as bird health, lack of materials or any other issue that may arise, these can be identified quickly, so you can start determining the optimal action plan. You can also use an advanced planning system to simulate scenarios to see what will happen if you take action. For example, maybe you are not able to fulfill an order in one day, but you plan to fulfill it in two days-what will happen, and how will it affect your plan? By running this test before you make that decision, you’ll be able to see if this is the best course of action and if not what your alternative options are.

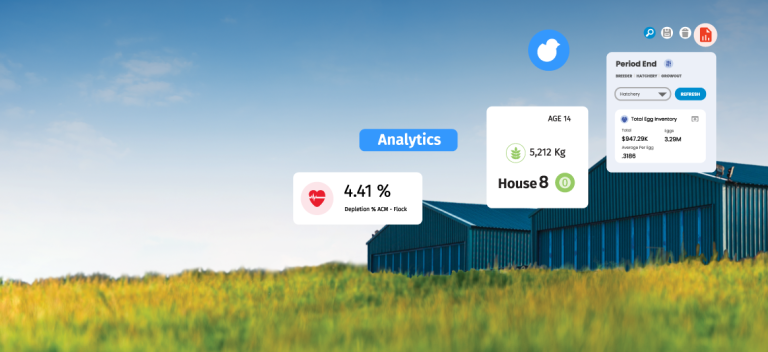

Optimize product mix impact in processing and achieve proactive financial margin management by processing plant planners. In addition to executing your daily sales orders by demand, your system can help drive your sales with long-term planning as well. You can use a planning software to help you understand, based on the birds, capacity and materials you have, what is the best production plan. The system will consider all the data in the system like profitability based on market, production costs, live animal costs to then be able to tell you answers to questions like what markets are best to target, what mix of products are my most profitable and many others.

Proactive staffing level management to execute optimal product mix – labor efficiencies, a planning system can tell you if you have the right number of staff to fulfil your orders. In addition to this with long-term planning you may decide you want to add on an additional market, but then the system might show you don’t have capacity to handle it, you will be able to decide if you want to hire more people or If you need to add a new line to help you reach that goal. You can run a simulation to find what would happen if you added more staff, add a line or add extra equipment or any other scenario you want to run, and the system will show you the expected result.

Meet the changing sales demand: Proactively manage the production of the right product. Sometimes your daily or short-term plan might alter your long-term plan. When this happens, you will be able to re-run your projection and see how it will impact your plan. Maybe you get a call from a customer, and they want to delay or don’t need to order anymore, or maybe another customer might say they want you to produce 2% more on their order. Because there are so many changes that can occur, it is pertinent that you have a planning system that offers you the flexibility and speed you need to run and scale your operation.

Speed of scenario planning: See the impact of every decision before you even make it. You may have a spreadsheet currently that does very basic calculations where you plug in your demands and supplies, and it gives you an output. But if you want to start simulating what will happen if you do something, this is practically impossible in a spreadsheet. You could try to run scenarios in a spreadsheet but will most likely end up with issues, mistakes and the process is very complicated. In an advanced Artificial Intelligence-based planning system, these simulations can be done in seconds.

There is no comparison between a spreadsheet and the Proline system.

Daniel Gustavo- Proline Product Owner

See how this works in the example below:

What will impact my profit margin most?

In these what-if scenarios, we are comparing scenarios like if we decide to process all the birds and produce 9-piece cuts products versus producing breast fillets + wings/leg quarters to a specific market such as China.

In Proline, you can build multiple scenarios and compare to see which option will bring the most impact.

Other questions that can be answered: Which scenarios would provide lesser leftovers, better machinery utilization, lesser production costs and more.

Improve planning and business results with Proline

If you want to have the most optimal plan, spreadsheets don’t always cut it with their basic supply and demand inputs and outputs. With Proline, you will be able to do modern agile planning and easily simulate what-if scenarios to make the best decisions possible for your processing operation. You’ll also be able to identify ways to streamline your operation and reduce the chance of human error, formula miscalculations, increase accuracy/efficiency, and quickly pivot whenever needed. In Proline, you can compare multiple projections at once from machinery utilization to costs to production output and much more.