Interview with David Caldwell, Ph.D., director, Center for Poultry Science, and professor and head, Department of Poultry Science, University of Arkansas

MTech Systems & Munters are proud to partner with the University of Arkansas to help with data stewardship and to invest in the next generation of farmers. Recently we sat down with Dr. David Caldwell to hear his thoughts about the project and its expected impact it will have on the industry and the next generation of poultry farmers. You can check out the interview below.

What type of research do you plan to do with the farm and the setup you have?

“So we tried to go into this project with an approach that would allow us to be as versatile as possible. So we have an east end of the building that will be set up with modular floor pins about four by six feet in, in size, really set up well for doing, let’s say, nutrition studies, measuring performance parameters with different dietary treatments or experimental groups. But also, we tried to design the pin configuration so that it can be as versatile as possible, if we needed to convert to larger pens or slightly smaller pens, we’d be well set up there to do so. So I think in that end of the facility, it ought to lend itself well to management applications, possibly lighting, but really, I expect a big focus there to be on nutrition. I think we’ll have our nutrition issues at that end of the facility frequently.

The West End of the barn, which has a larger footprint, it’s larger overall floor space, it’s set up with much larger pins, and we have a 20 by 30, floor pins in that end of the facility. We also have automated feeder lines, so hand feeding won’t be necessary. In that end, we have eight external bins, feeding eight total 20 by 30 pins. And there we could get into some breeder-type work applications, or possibly evaluate some of the slow-growth breeds. But really, we have an enhanced capacity there to look at larger bird numbers and actually approach a setting that that would more mimic commercial setting, with a lot of birds in the environment. And that’s what we’re striving for In that end of the, of the facility, and that is also where we have most of the sensor technology. So, we will be getting into real-time data collection, everything from relative humidity to airspeed to co2.

But what that’s going to enable us to do really for the first time is collect to a great deal more data, and pull it into our investigations and, and really enhance our capacity to report on more parameters than just performance parameters, just feed conversion, and just bodyweight gain and average daily gain. So we’re really excited. This is a new territory for us. And we’re really excited to work with MTech Systems and Munters, to really expand our capacity in this way.“

So how will this research help the industry with all this data that you’re going to be getting?

“A lot of the input is on design and the way that we’ve configured the facility, it does come from, you input from some of our most important stakeholders, primary breeder companies, broiler integrators. So we’re very hopeful that the data that we generate in this facility will be quite useful for them as well. We see a huge benefit from this facility from the perspective of getting our students in there and getting them exposed to the best technology that’s out there in the commercial industry right now in production houses and advanced controllers and sensors. Really the rest of our research farms in our teaching facilities, I think are very functional, but they won’t have as many bells and whistles as what we’ll see in This particular house, so we’re excited about the opportunities for education and training just as much as we are about the opportunities for research.“

Why do you think MTech Systems and Munters are great partners for this project? And what is your viewpoint on the value that we will be providing?

“This is a new experience for us, this will be the most technologically advanced facility that we operate, and that provides great benefits for training students and helping our faculty members really expand what they can do with their research programs. And honestly why working with MTech Systems and Munters has been beneficial because that’s the name that I’ve heard so frequently, on sensor technology. I don’t know a lot about sensor technology. This is a new venture for most of us here. But We were typically directed towards your brand.“

What are your thoughts on how this technology will change the future of the poultry industry?

“We have a really automated facility -a new type of ventilation system, really, it’s not your standard tunnel ventilated facilities, It’s got the plenum type design for conditioning air before it’s brought into the facility, which is supposed to get us really tight environmental control. I am hopeful that a lot of these observations will help integrators really learn more about housing and help them make decisions when they’re building new houses or new facilities. So we’re hopeful that a lot of that will translate.“

What is the role that data plays in the advancement and growth of the poultry industry?

“I think it’s going to be huge, actually with talking to live production managers, and SVPs, of live production and with integrators in our area here there’s a huge focus on data and what we can do with data as well as how it can be analyzed and processed and then translated into value. I mean, we seem to live now in a very data-hungry world. And I think that is only going to increase. I don’t really see us moving away from that. So the more data we have, the more accurate data we have, I think we can make better, more informed decisions.“

How do you foresee this type of technology and data stewardship impacting the next generation of farmers? And how can we as an industry leverage technology to better equip this next generation of growers?

“That’s one of the things we’re most excited about is that we’re going to learn from this process we’re going to learn when we begin using this facility. And that’s going to help our Extension specialists, that’s going to help our researchers be able to share observations and data with integrators and with contract producers, and I think it’s going to put us in a better position to really share more relevant recommendations and, best practices. It’s going to equip us better to be able to help integrators and growers.”

Learn more about the precision farming technology that will be used at this facility

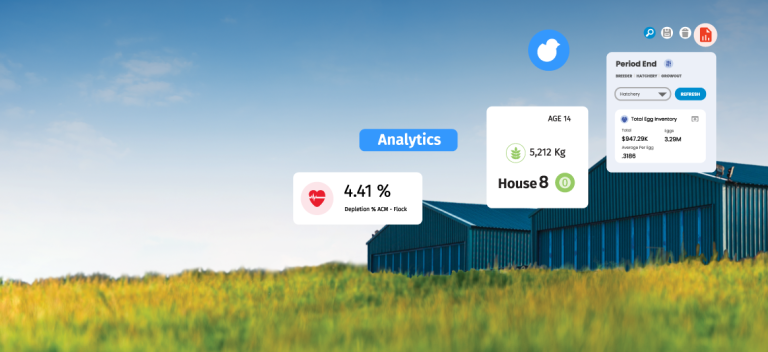

Sonar is an IoT system that connects your farm through sensors, scales and controllers allowing automated data capture, custom alerts and tailored analytics for your business.